Gray Cement

General use

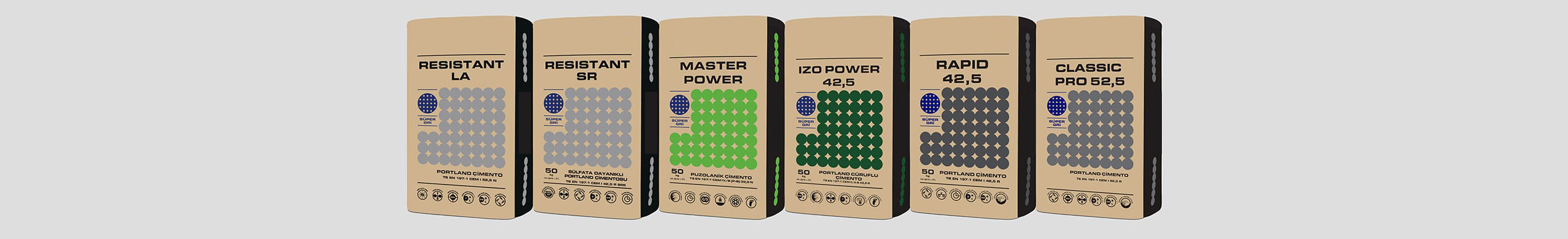

PCM gray cement family offers a wide range of solutions for different needs such as fast production possibility, high durability, sustainable feature, controlled hydration heat, high strength, resistance to sulphate, low alkali content or optimized setting time.

Ready-mixed concrete

It is appropriate to use Çimsa Portland Cement, Portland Slag Cement and Portland Calcareous Cement in ready-mixed concrete production. PCM Portland Cements provide the solution to achieve sufficient initial strength, including when pouring concrete in cold weather conditions. PCM Portland Slag Cement and Portland Calcareous Cements have insulation, better workability and early strength gains compared to their class. It can be used with all typical concrete admixtures (e.g. plasticizer, air entrainer and set retarder admixtures).

Construction chemicals

It is appropriate to use PCM Portland Cement, Portland Slag Cement and Portland Calcareous Cement in the production of construction chemicals. It is suitable for the production of joint filler, tile adhesive and various construction chemicals. PCM Portland Slag Cement and Portland Calcareous Cements have insulation, better workability and early strength gains compared to their class.

Precast

CEM I 42.5 R and CEM I 52.5 R type Portland cements are designed to achieve rapid strength development in concrete. They provide higher early strength without any significant change in setting times or workability times. It is ideal for use in prefabricated element applications to reduce mold removal time as it provides high early strength. It increases the speed of precast production by allowing early removal of formwork. Complies with chloride content limit requirements for prestressed concrete. Producing more heat with its fast reaction time brings an advantage that can be useful in cold weather conditions. Helps offset the effects of low ambient temperatures.

Special Application Areas

PCM also offers many solutions for special project applications with Sulphate-Resistant Portland Cement when it is desired to produce highly sulphate resistant concrete against possible sulphate effects that may cause durability problems, or with Low-Alkali Cement to reduce the alkali-aggregate reaction potential. It meets expectations with its 52.5 strength class cements for projects with high performance targets in end products such as high-strength concrete and thin-section reinforced concrete structural elements.

Plaster-Mortar

PCM CEM II/BL and CEM IV/B type 32.5 strength class cements are designed for general purpose use for building applications such as mortar, plaster, screed, coatings and insulation. Construction limes and plasticizer additives are compatible. They provide improved workability, consistency, finish and durability for easier processing. Complies with the chromium (VI) guideline to reduce the risk of allergic dermatitis upon contact.